| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : NEI

Model Number : Matte

Certification : ISO9001 / ISO14001 /SGS Test Report

Place of Origin : China

MOQ : one ton

Price : Negotiable

Payment Terms : L/C, T/T

Supply Ability : 1000 Tons per month

Delivery Time : 15 -20 working days for one 20GP Container

Packaging Details : 1. Packed in paper cartons firstly and then secured on wooden pallets. 2. All pallets are well packed with packing belts and well wrapped with stretch film.

Product Name : BOPP Thermal Lamination Film

Type : Thermal Lamination Film

Material : BOPP+EVA

Transparency : Transparent

Application : Lamination For Offset Printing

Glossy and Matte Transparent BOPP Thermal Lamination Film With Glue 15mic to 43mic

Specifications:

| TYPE | THICKNESS (micron) | ||

| Matt | TOTAL | FILM BASE | EVA GLUE |

| 17 | 12 | 5 | |

| 18 | 12 | 6 | |

| 20 | 12 | 8 | |

| 22 | 12 | 10 | |

| 23 | 15 | 8 | |

| 25 | 15 | 10 | |

| 27 | 15 | 12 | |

| 28 | 15 | 13 | |

| 30 | 15 | 15 | |

| 43 | 18 | 25 | |

| WIDTH (mm) | 200 ~ 2200 | ||

| LENGTH (m) | 100 ~ 5000 | ||

| PAPER CORE | 25.4mm(1 inch) / 76mm (3 inch) | ||

| BONDING | ≤2 | ||

| CORONA TREATED | Double side | ||

| SURFACE TENSION | 38 Dyne/cm ≤ 42 Dyne/cm | ||

| LAMINATION TEMP. | 90±10°C | ||

| ROLLER PRESSURE | 10 ~ 20Mpa | ||

| LAMINATION SPEED | 20 ~ 70M | ||

Description:

The surface of the thermal adhesive film is extruded and coated with a layer of low-temperature molten resin, and the film is bonded to the paper product through heat and pressure. The various surface treatments on the printing surface have added value. BOPP thermosensitive laminated film provides a matte finish on the printed surface.

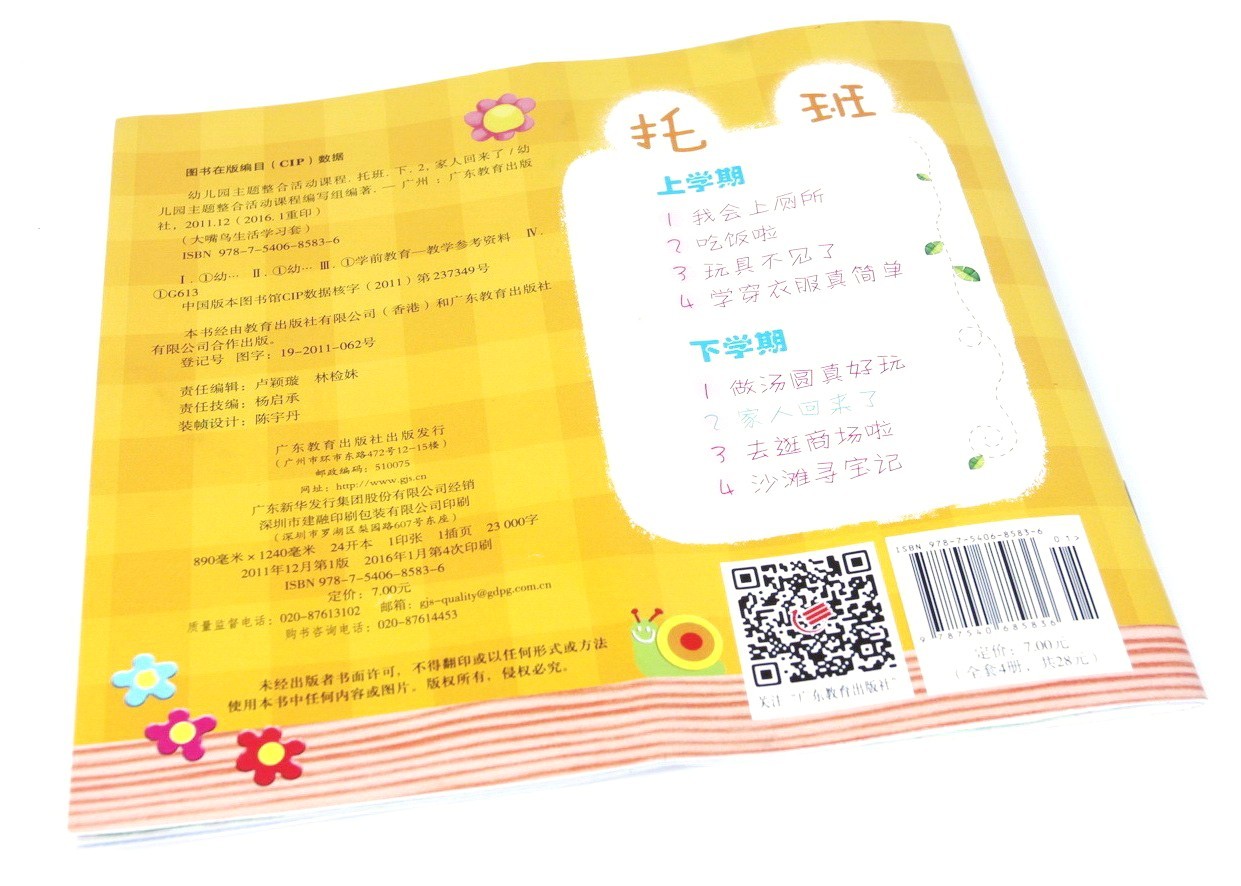

A combination of good performance characteristics and low price point make BOPP Thermal Lamination Film ideal for all kinds of printed & unprinted paper and paper boards, including book covers, cosmetics packaging, magazines, documents, shopping bags, Diaries etc.

Why chooses NEI BOPP Thermal Lamination Film?

Environmentally friendly: It is environmentally friendly, not harmful to health and safe to use as it does not emit toxic gases or volatile substances. Safety during lamination because no solvent-based adhesives are used.

High performance: Compared to other solvent based laminates, our film has better transparency and adhesion. Strong powder absorption ability, preventing the laminated board from being squeezed, bubbled, and crushed. The sub light thermal lamination is suitable for spot UV and hot stamping.

Easy to operate: Once the desired temperature is reached, the operation is simple and no special processes are required. Efficient and energy-saving: Production costs are greatly reduced as there is no need for a mixture of film waste, adhesive solvents, or UV heating lamps.

Suitable for different types of machines: Recommended for dry laminating machines. If the film is used in a wet laminating machine, fine adjustments need to be made to the machine.

Why chooses NEI?

Special Instruction:

The recommended laminating roller temperature range for NEI BOPP hot press film is 85~110 ℃, and the rolling range is 10~20mpa. However, the optimal conditions depend on the speed and dimensional stability of the selected laminating machine.

It is recommended to dry the printed surface thoroughly before laminating and cool one surface thoroughly before laminating onto another surface.

Applications:

Packaging:

|

|

BOPP Thermal Lamination Film With Glue, Matt/Glossy 15mic-43mic Images |